Rock Testing Laboratory

Laboratory Director: Dr. Marion Nickmann

The rock testing laboratory is available to the members of the department for research and investigations on permanent and variable solid rock samples. The core of the laboratory is the equipments for rock strength testing, such as the force/deformation controllable ToniNorm compression test facility with one 2000 kN and 200 kN test frame each or the point load devices that can be used both in stationary and mobile setting. The assessment of tool wearing can be carried out by Cerchar abrasivity testing. However, mineralogical-petrographic methods such as thin section microscopy, scanning electron microscopy or X-ray diffraction are increasingly applied in rock investigations.

Uniaxial Compression Test

with digital recording of longitudinal and optionally transverse deformation for determination of unconfined compressive strength (UCS), elastic properties (Young's modulus, Poisson's ratio) and specific destruction work (Wz) (according to THURO)

Point Load Test

for indirect determination of the compressive strength or tensile strength of cubes, cylinders or irregularly shaped test specimens

Abrasivity Tests

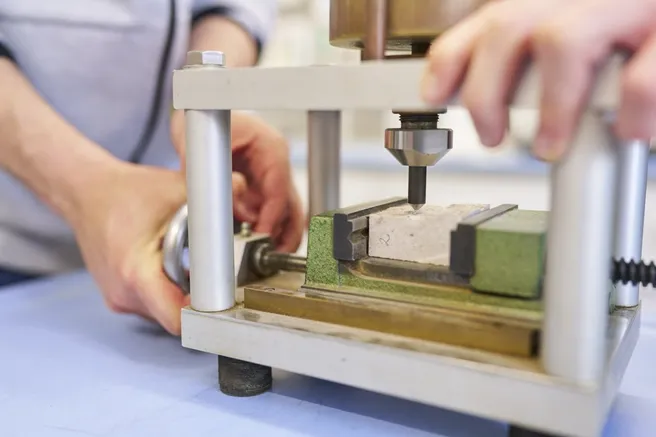

Cerchar Abrasivity Test

Determination of the Cerchar abrasivity index (CAI) to evaluate rock abrasivity

LCPC Abrasivity Test

Determination of the LCPC abrasivity coefficient (LAK) and the LCPC crushability coefficient (LBK) to evaluate rock abrasiveness and crushability

Petrographic-mineralogical Investigations

Production and evaluation of thin sections, qualitative and quantitative evaluation of the mineral content in thin sections, determination of the equivalent quartz content, determination of wear indices (VHNR, Schimatzek index, modified Schimatzek index), investigations with the scanning electron microscope, semi-quantitative investigations with X-ray diffractometry

Brazilian Test

carried out on cylindrical test specimens

Investigations on Variable Solid Rocks

Crystallization Test

with Glauber's salt solution to assess the weathering resistance of rocks according to DIN 52111

Variability Test according to NICKMANN (2009)

Nickmann, M. (2009): Abgrenzung und Klassifizierung veränderlich fester Gesteine unter ingenieurgeologischen Aspekten. Technische Universität, München.

Sieve drum test according to FRANKLIN & CHANDRA (1972)