Introduction

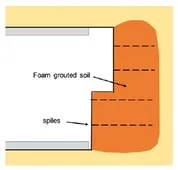

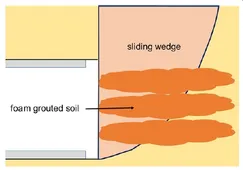

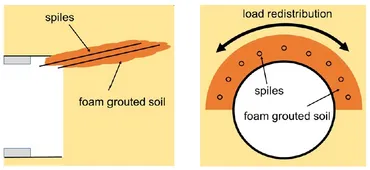

When using the shotcreting method in coarse-grained soils with no cohesion, the tunnel face can only be excavated with massive additional effort. Conventional measures to

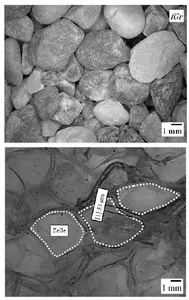

guarantee a safe tunnel advance are work- and time-consuming. Pre-injection grouting with foam is an alternative and innovative solution to stabilize the soil at the tunnel face.

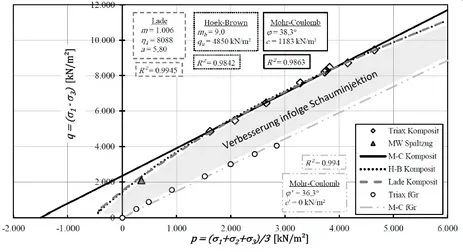

The individual grains of the soil are cemented together and a stable geocomposite material is formed. Currently there are no existing tools or material models for geotechnical

description of the soil improvement by foam grouting.

Application fields at the tunnel face

Advantages of tunnel face stabilization by foam grouting in comparison with cement injection

• Reduce grout material consumption due to fast curing process and volume

expasion

• Increase rate of advance

• Reduce excavation masses due to low density of the foam

• Simple construction site equipment (no bentonite mixer and silos)

• Reduce of anchors to stabilize the tunnel face

• Reduce tunnel induced displacements