Overview

Ongoing research projects:

- AiF-FOSTA 21403 N - Load-bearing behavior of shear studs in composite floor decks with high ribs under fire loads

- DLR-FOSTA-Project: IGF-Number 23408 N, FOSTA P 1778 - Reliable design concept for hollow section composite columns with high-strength and hybrid cross-sections on a uniform basis

- DLR-FOSTA-Project: IGF-Number 23281 N, FOSTA P 1727 - Beam-column and floor-column connections of high-performance composite columns made of high-strength steel

- ZIM-project KK5547104KT4 - Development of a multifunctional ceiling system in steel-timber hybrid construction

- FOSTA P 1801 / IGF Number 01IF23557N, FOSTA P 1801 - Discrete load application with headed studs in bridge and building construction

Completed research projects:

- AiF FOSTA P 1500 - Composite Columns with Sheet Metal Sections using High Strength Steel

- AiF FOSTA P 1349 - Bar bundle columns with high-strength reinforcing steel

- AIF 15609 N – Flexible secondary beam connections with long flange plates in composite construction

- Zukunft Bau – Development of thin-walled, planar structural elements made of UHPC and suitable joining techniques for its usage in building construction and industrial engineering

- AIF Zutech – FOSTA P 881 Construction of sustainable offices and administrative buildings using steel and steel composite construction

- TopFLOOR INTEGRAL - Development of a sustainable composite floor system

Discrete load application with headed studs in bridge and building construction

- FOSTA P 1801 / IGF Nummer 01IF23557N, FOSTA P 1801

- Timeline:

Project partners:

Steel and composite structures are an economical and well-designed solution for bridge construction, with an increasing focus on integral solutions. In these forms of modern bridge construction, structural components of steel and composite structures are increasingly being connected to concrete structures using headed studs in a series arrangement. Constructions with a large number of headed studs for the introduction of discrete loads have other advantages in addition to cost effectiveness and are therefore often chosen by planning engineers.

Complex questions regarding the load distribution between the dowels arise not only from the non-linear headed stud characteristic curve during initial loading and reloading, but also from the behavior of the concrete structure, which is partly subjected to tensile loads, so that a possible crack formation in the concrete can lead to a significant load redistribution within the headed stud group.

The aim of the research project is therefore to develop rules for the design of the discrete load transfer from a steel component into concrete using large groups of shear-loaded headed studs in bridge and building construction. This results in scientific questions regarding the stiffness-dependent activation of the individual mechanisms at the load transfer. The distribution of the total load on the headed stud group depends on the stiffness of the headed studs during initial loading, but above all during reloading.

Tensile, compression and bending tests will be used to investigate the load application and the change in stiffness of the headed studs and headed stud rows. Based on these test results, numerical models will be created and validated in order to expand the parameter space with the help of further investigations. Based on the experimental and numerical results, concepts for the design of the load application are developed.

Responsibility

Development of a multifunctional ceiling system in steel-timber hybrid construction

- ZIM-project: KK5547104KT4

- Timeline: 01.01.2025 - 31.12.2026

Project partners: ABA Holz van Kempen GmbH, KoRoH GmbH, H. Wetter AG

As part of the ZIM funding program, the Chair of Metal Structures, together with the project partners ABA Holz van Kempen GmbH, KoRoH GmbH and H. Wetter AG, is developing a sustainable hybrid ceiling element made of steel and timber in an R&D cooperation project. Each ceiling element consists of a large-format cross-laminated timber panel and two steel profiles with a T-shaped cross-section. The bond is to be created as far as possible via geometric positive locking. The focus is therefore on the economically, technologically and ecologically optimal design of the composite joint. Experimental and numerical investigations and the derivation of a design concept are part of the project of the Chair of Metal Structures.

Responsibility

Beam-column and floor-column connections of high-performance composite columns made of high-strength steel

- DLR-FOSTA-Project: IGF-Number 23281 N, FOSTA P 1727

Timeline: 2024 - 2026

In recent years, the use of high-strength steels has led to the successful development of new types of high-performance columns in composite construction. These not only have a particularly high load-bearing capacity and very good behavior in the event of fire as unique selling points, but also achieve extremely high resource efficiency thanks to their particularly slim cross-sections. In this research project, specific connection solutions are to be developed for optimum use of the new high-performance composite columns and backed up with design concepts to enable safe and simple connection of beams and ceilings to such columns.

One challenge here is the very local and concentrated load transmission through the floor construction at column joints. In addition, the loads from connected components must be transferred directly into the column core in order to ensure the transfer of large loads even in the event of a fire. A further requirement is the economical manufacture and assembly of the connecting structures to ensure their practical applicability.

With the help of large-scale tests on connections of composite and slim floor beams as well as solid floors to high-performance composite columns, the load-bearing capacity of the connecting structure at room temperature and in the event of fire as well as the clamping effect of the column in the floor structure are to be investigated. As the load-bearing capacity of high-performance composite columns depends largely on their buckling length, a reliable assessment of the degree of restraint at the column head and the associated reduction in buckling length enables more efficient design of the high-performance composite columns. The high plastic normal load-bearing capacity of the high-strength steel can thus be better utilized even with longer buckling lengths.

Numerical models are to be created and validated on the basis of the test results in order to expand the parameter space with the help of further investigations. Based on the experimental and numerical results, concepts for the design of connections of high-performance composite columns can be developed.Responsibility

Reliable design concept for hollow section composite columns with high-strength and hybrid cross-sections on a uniform basis

- DLR-FOSTA-Project: IGF-Number 23408 N, FOSTA P 1778

Timeline: 2024 - 2027

Composite columns are a slender and load-bearing alternative to solid concrete columns in high-rise and industrial buildings. Current research has shown that the use of high-strength steels in composite columns can further increase the load-bearing capacity and thus contribute to highly efficient structures. The HOCHFEST research cluster of FOSTA e.V. has developed and investigated various construction forms for the design of such hollow section composite columns with set core profiles. To date, however, there has been no basis for a uniform design concept for the hollow section composite columns investigated.

Previous design approaches according to EN 1994-1-1 proved to be insufficient for the mathematical design of the new types of construction using high-strength steels. The use of high-strength steel grades brings with it new phenomena that must be taken into account when calculating the loads. On the basis of previous research, it is now possible to quantify these influences in more detail and to derive probabilistic parameters with supplementary experimental tests that enable reliable design of high-strength composite columns. At the present time, there is also no or only insufficient knowledge of the effects of buckling of composite columns in floor systems. By taking these into account, buckling lengths and thus slenderness could be reduced so that the load-bearing capacity reserves of the steel used can be efficiently utilized.

The aim of this research project is to develop a uniform design approach for new composite column constructions made of concrete-filled hollow sections with high-strength steels at room temperatures. A simplified verification procedure for these composite columns under fire exposure, which is based on the verification concept at room temperature, is also to be developed. The influencing parameters will be determined in a standardized way and verified by systematic probabilistic analyses.

The intended results of the research project will make it possible to take into account the special requirements that the newly developed, high-strength composite columns entail and to design them using a uniform, consistent concept, both for room temperatures and under fire exposure.

Responsibility

Load-bearing behavior of shear studs in composite floor decks with high ribs under fire loads

- AiF-FOSTA-Project: IGF-Nummer 21403 N

- Timeline: 2021-2023

Composite slabs, consisting of steel composite profiled sheets and concrete, have been used successfully in composite construction for many years. In many cases, their cost-effectiveness depends on the span widths that can be achieved with the profiled sheets in the construction state. In order to increase the span widths, profiled sheets with high ribs are becoming used more frequently, which can minimize the number of secondary beams required and significantly increase the cost-effectiveness of the construction method.

The use of ever higher profiled sheet heights changes the load-bearing behavior of the shear connectors required to create the connection between the composite deck and the beam to greater flexibility and ductility, but also to a lower load-bearing capacity. In contrast to the application of profiled slabs in cold conditions, hardly any research results are available for fire conditions. Therefore, it is currently not possible to make any well-founded statement on the applicability of the design formula for the load-bearing capacity of head bolt anchors in case of fire according to DIN EN 1994-1-2 for high-rising profiled anchors.

Building on the already completed research project "Minimum anchoring of composite girders in the event of fire", the applicability of partial composite anchoring in the event of fire is also to be examined in greater detail. It is to be examined whether the approaches developed for composite girders with solid concrete slabs can also be transferred to composite girders with high-rising profiled sheets.The implementation of the research objectives is to be achieved by an extensive experimental test program. While the local load-bearing behavior of the shear studs in the profiled sheet beads is to be investigated by means of push-out tests in accordance with DIN EN 1994-1-1 under fire load, the overall load-bearing behavior is to be analyzed by means of large-scale fire tests on composite girders. In addition to the test program, parameter studies on composite girders and push-out test specimens are planned using the Abaqus FE software.

Responsibility

Composite columns with high-strenth steel plates as core

- AiF-FOSTA-Projekt: IGF-Nummer 21366 N1, FOSTA P 1500

- Timeline: 2020-2023

- Cooperations: Technical University of Braunschweig, Institute of Building Materials, Concrete Construction and Fire Safety Division Fire Safety and Industrial Partners

This research project deals with the development of a neoteric composite column, with cross-section of steel plate fins (Fig. 1). It consists of steel lamellae that are inserted in a steel tube and grouted with high-strength mortar. By using ultra-high-strength steel for the slender lamellae (with yield strength up to 1100 N/mm² and maximum thickness 40mm) as well as for the tube profile (yield strength up to 890 N/mm²) simultaneously, extreme load bearing columns can be developed.

The use of plate lamellae vis-à-vis full solid section provides added benefits because of these two reasons:

1. By using a single plate thickness of maximum 40 mm, the reduction in thickness-dependent yield strength (mainly arising due to internal residual stresses) are avoided. As with increase in plate thickness the level of residual stresses increases, because of the manufacturing process involved, which leads to early arrival of yield strength.

2. In the event of fire, by breaking the heat conduction between the steel lamellae more advantageous heating behavior can be obtained. (Fig. 4)

The individual plates are selectively joined, at specific points to set the necessary bending stiffness as required. For this purpose, various connection mechanisms are being examined such as prestressed bolted joints, stitch (partial) welding and full-length welding. The choice of various shear connections enables the possibility of achieving best targeted configuration, ideally without causing any additional residual stresses or disturbances in the high-strength steel.

To summarize, the use of high strength materials and innovative section design allows the development of extreme high load-bearing composite columns. The local use of shear connection offers an efficient way of manufacturing.

Responsibility

Michael Schäfers

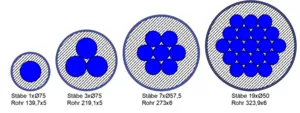

Bar bundle columns with high-strength reinforcing steel

- AiF-FOSTA-project: IGF-number 20352 N, FOSTA P 1349

- Project timeline: 2019-2021

- Project partner: Technical University of Braunschweig,Institute of Building Materials, Concrete Construction and Fire Safety, Division of Fire Safety and industrial partners

The aim of the research project is to develop fire-resistant, high load-bearing and simultaneously slender composite columns.

Bar bundle columns are a new type of composite column. For this purpose, a bundle of high-strength reinforcing bars with a yield strength of 670 N/mm² is set in a steel tube and then grouted with mortar. The bundle can consist of 1,3,7 or 19 bars.

These steels are available on the market up to a diameter of 75 mm. A thickness-dependent yield strength reduction is not required here, so that the high yield strengths can be fully utilized. By bundling bars, high filling ratios of the cross sections are also possible, so that load-bearing capacities can be achieved that are otherwise only possible with much larger cross-section dimensions.

Compared to composite columns with solid cross-sections, bundled columns also exhibit more favorable heating behavior because the individual bars are only in direct contact with each other at specific points, thus limiting heat conduction between the bars.

Within the scope of this project, the load-bearing behavior of bar-bundle columns in cold and fire conditions was investigated. In order to analyze the load-bearing behavior, the individual material parameters were determined in cold and fire conditions. Subsequently, large-scale tests were carried out; an FE model was created or calibrated from the collected results. With the help of the FE model, numerous parameter studies were carried out, on the basis of which a design concept based on DIN-EN-1994 was created so that the columns can be used in practice.

The final report will be published shortly by FOSTA (Forschungsvereinigung Stahlanwendung e.V.).

Responsibility

Research Funding

AiF - Arbeitsgemeinschaft industrieller Forschungsvereinigungen

FOSTA - Forschungsvereinigung Stahlanwendung e.V.

The IGF project "Bar bundle supports with high-strength reinforcing steel" (IGF project no. 20352 N) of the Forschungsvereinigung Stahlanwendung e. V. (FOSTA) is a sub-project of the FOSTA research association HOCHFEST and was funded via the AiF within the framework of the program for the promotion of joint industrial research (IGF) by the Federal Ministry for Economic Affairs and Climate Protection on the basis of a resolution of the German Bundestag. We would like to take this opportunity to express our gratitude for the funding.

Construction of sustainable offices and administrative buildings using steel and steel composite construction

Download Sustainable Office Designer (SOD) →

SketchUp Extension Warehouse →

- AiF-Zutech-Project P881

- Project period:

- Project partners: Technical University of Dresden, Institute of Steel and Timber Construction; RWTH Aachen, Chair of Steel and Light Metal Construction; Technical University of Darmstadt, Department of Design and Building Design, Institute for Technology and Work e.V., Kaiserslautern, Technical University of Kaiserslautern, Chair of Management Accounting and Controlling.

Within the scope of AIF-Zutech Project P881 the construction of sustainable offices and administration buildings in steel and steel composite construction, planning tools and methods for the design and evaluation of these buildings are developed by an interdisciplinary research team. Apart from ecological and economic criteria, architectural, socio-cultural and socio-technological criteria are also taken into account. The benefit of their flexibility and their evaluation are in focus, as this has significant consequences on buildings’ design and their subsequent marketability. Based on various usages, developments and trends in the structural organization of office buildings, the socio-cultural and socio-technological requirements are formulated. Strategies for life-cycle-oriented economic evaluation are developed, including value-added accounting. The development of sustainable load-bearing structures in steel and steel composite constructions are one of the construction-related topics. The Chair of Metal Construction at TUM is leading the project and developing intuitive CAD-supported software for the ecological optimization of the steel load-bearing structure of office buildings with the help of genetic algorithms, which enables a right direction to be set during early design phase with respect to a particular ecological building design.

Responsibility

Development of thin-walled, planar structural elements made of UHPC and suitable joining techniques for its usage in building construction and industrial engineering

- Zukunft-Bau-Project: SF-10.08.18.7-11.14

- Project period:

- Project partners: SSF Ingenieure AG, Munich; Max Bögl GmbH & Co KG, Neumarkt; Hetschke Bau GmbH, Bautzen; Chair of Solid Construction, TU Munich and Federal Institute for research on future construction of building, urban affairs and spatial development.

Large spans, high load-bearing capacities, improved robustness and durability properties can be achieved by using innovative materials such as Ultra High-Performance Concrete (UHPC) with a compressive strength of more than 150 N/mm². The use of such high-performance concrete also meets the requirements for material and resource saving structures which is in congruence with sustainable construction practices by reducing cross-sectional dimensions. The objective of this research project, being headed by Chair of Concrete Structures at TUM, was the development of load-bearing wall elements made of UHPC with reduced wall thicknesses of approx. 3 - 6 cm. In order to enable its use in practice, it was necessary to develop fasteners that were suitable for this material and adaptable to frame dimensions. However, it is also necessary to investigate the stability behavior (plate denting and buckling) of such thin wall elements in order to achieve economical application. Large format UHPC wall panels are particularly suitable for use as precast elements in building and industrial construction.

Responsibility

TopFLOOR INTEGRAL - Development of a sustainable composite floor system

- Project period: from 2008

- Project partner: H. Wetter AG, 5608 Stetten AG, Schweiz und ETH Zürich

Sustainable building requires innovative construction methods such as a resource-saving innovative TopFLOOR INTEGRAL ceiling system. Together with ETH Zurich and H. Wetter AG, Stetten, a Swiss steel construction company, a sustainable multifunctional ceiling system in composite construction was developed in which the installation level or raised floor is integrated into the static construction height. The system consists of half honeycomb girders that are connected to a concrete slab in a shear-resistant manner using conventional reinforcement bars, thus forming a pi-slab allowing large spans and column-free constructions. Depending on the requirements, the slabs can be used in positive or negative position. Design concepts were developed and tested for system and necessary connection details. Intensive investigations against vibration behaviour of the structure were carried out at Chair of Building Mechanics at TUM. This construction method reduces material consumption by approx. 50% as compared to conventional concrete structures. TopFLOOR INTEGRAL has meanwhile been proven outstanding for several buildings in Switzerland allowing the shortest possible construction times. For example, the shell including the facade of the eight-story Lindenplatz school building in Baden (CH) was erected in less than 10 weeks over a rail tunnel.

Responsibility

Flexible secondary beam connections with long flange plates in composite construction

- DASt-AiF-project (AiF 15609 N)

- Project period: 2007-2009

- Project partners: In cooperation between German Committee for Steel Construction and various industrial partners

Flexible secondary beam connections are the most common, but at the same time least researched connection types in steel composite construction. In steel and composite construction, the connection of secondary beams to main beams is often made with long flange plates since these are easy and inexpensive to manufacture. In the past, flange plate connections were considered to be ideally flexible, although an unplanned continuity effect occurs with secondary beams over two or more spans. Because of the continuity of concrete section of secondary girders across the main girders, the continuity becomes relevant for composite girders. Within the scope of this research project, fundamental findings on actual load-bearing behaviour of such secondary girder connections were obtained with the help of large-scale tests and corresponding numerical simulations. Based on these findings, a design model was developed for practical applications. An essential component of the model is a plastic moment-shear force interaction relationship, derived individually for the respective connection, with the help of which the moment load capacity of the connection can be determined quickly and easily as a function of acting shear force. Consideration of the moment capacity of the connections allows a more economical design of the secondary beams than if the connections were considered in a hinged manner.

The research report can be obtained from the German Committee for Steel Construction (DASt).