Identification of load-bearing properties of laminated glass under prolonged load exposure, low temperature, and alternating exposure conditions

- DFG-project: DFG ME 3296/1

- Project period:

- Project partner: University of Applied Sciences, Munich

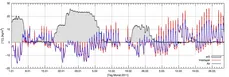

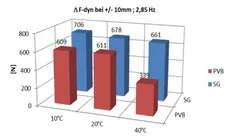

The load-bearing capacity of Laminated Safety Glass (LSG) can be significantly increased by considering the composite shear load-bearing effect of polymer interlayer materials. In this research project, in collaboration with University of Applied Sciences, Munich, the time and temperature dependent composite properties were investigated at low temperatures for prolonged loads. Long-term measurements of overhead glazings were carried out on two outdoor test rigs to determine the snow load characteristics and service life, the arising interlayer temperature correlations and the long-term mechanical behaviour of laminated safety glass panes. These tests and accompanying creep tests at low temperatures under laboratory conditions confirm that, even for conventional components, rather creep-sensitive materials such as PVB, effective shear bonding is present at low temperatures under the effect of snow. In addition, the shear bond and fatigue behaviour of laminated safety glass were investigated for dynamically stressed and transparent noise barriers for a wide range of operating temperatures, along railroad lines, under short-term and frequently repeated stresses. With a view to have an efficient investigation of the mechanical durability of laminated glass at high numbers of load cycles, a fatigue test rig was also developed and set up.